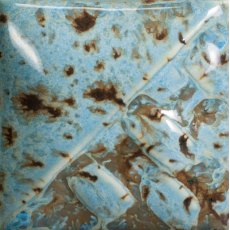

Winter Wood Mayco Stoneware Glaze

Description

Stoneware crystal glazes are designed to expand upon the surface with dazzling bursts of color. Fired results will vary based on ware’s orientation. Crystals will settle to the bottom of the jar and will need a good mixing prior to initial use. Re-stir between each coat. Stir with palette knife or other unpainted tool. Avoid placing crystals near the bottom third of a vertical piece as they may cause additional movement during firing. Crystals will flow more than the base glaze. While the glaze is wet, use your fan brush to redistribute the crystals to achieve balanced coverage. Over-application or heavy deposition of the crystals can cause pinholing or running. When storing a crystal glaze, you may consider storing upside down to facilitate crystal dispersion on the next use.

1230°C (1st image): Winter Wood is a matte white glaze that contains a variety of brown crystals that melt.

1300°C (2nd image):Cone 10 reduction: Color changes to a translucent golden brown.

Tip: SW-106 Alabaster is the base glaze. For a lighter crystal effect, you may try applying two coats of SW-106 Alabaster with a third coat of SW-155 Winter Wood.

Size: 473ml Brush on liquid glaze.

Note: Due to the discontinuation of the AmTalc 98, Mayco have had to reformulate SW-106 Alabaster, SW-118 Sea Salt, SW153 Indigo Rain, and SW-155 Winter Wood. Users will notice a shift in the wet glazes (from grey to buff) and a slight shift in the fired color result. Please note that the fired result is dependent on firing temperature, atmospheric conditions of the kiln, application, and underlying clay body. The crystal loading has not changed. See below for the wet glaze color comparison of SW-106 Alabaster and the comparison of fired results on chips. Please see this link for more information (link to Mayco's website)

Health & Safety

Manufacturers Recommendations: Dinnerware Safe indicates the fired glaze surface meets the FDA standards for food safe, the fired surface is free of surface texture that could potentially trap bacterial, and the fired surface is chemically durable. Please note, dinnerware safety is not defined by cutlery scratches. Finished ware producers bear responsibility for dinnerware safe testing their ware being sold into commerce.

We at Bath Potters will quote the manufacturers recommendations, but if you intend to make ceramic dinnerware with selling in mind, then you would be best advised to get your wares tested.

Lucideon: https://www.lucideon.com/testing-characterization/ceramic-testing-analysis

Northern Testhouse: https://www.nthleicester.co.uk/service/homewares

Share

Winter Wood Mayco Stoneware Glaze

Facebook Twitter Email Pinterest Telegram